Jerguson V-Series Tubular Valves

and Assemblies

|

| Straight

pattern - Integral bonnet & offset - Bar stock straight

pattern - Integral bonnet & seat |

| |

The

simplest and least costly method of liquid level indication

is the tubular gage glass. Two slightly different designs are

available. Both are simply transparent vertical tubes

with their lowest visible point connected to the tank or boiler

at the lowest level of interest. The top of the glass may be

open to the atmosphere if the tank is open or to the unfilled

part of a closed vessel above or at the highest level permitted.

Isolating valves are placed above and below the gage glass

connections. One choice is a gage glass with slow closing valves and

the second choice are valves with quick closing type where

a one quarter turn of the valve spindle will change the valve

from the fully open to the fully closed position. The valve

spindles are fitted with levers to which chains may be attached

in order to operate the valves from ground level if the vessel

is located at a higher position. Drain valves or cocks may

also be installed below the gage glass to remove any solid

material that may collect.

Since

many tanks and pressurized vessels are not under continuous

supervision, a broken gage glass may allow a large amount

of fluids to escape. To prevent this, the lower valve on

the gage glass is often equipped with a safety shutoff device

consisting of a stainless steel ball which closes off the

fluid passage when the glass breaks. One disadvantage of

this type of safety device is that it requires more maintenance.

Under normal conditions, the steel ball remains in the recess

in front of the valve seat. However, when the gage glass

breaks, the sudden rush of fluid through the valve will force

the ball against the valve opening. This shuts off the flow

out of the broken glass.

The gage glass is usually surrounded by a number of metal

rods or transparent shield to protect the glass from breakage

and the operator from flying particles in case the gage glass

shatters.

The use of tubular gage glasses is limited to lower pressures

and temperatures, and restricted to non-toxic and non-hazardous

material. Tubular gage glasses should not exceed 750 mm in

length. If the level range to be observed exceeds this length,

then two or more gage glasses should be installed so that

they overlap.

|

| Types and

connections to suit all requirements: |

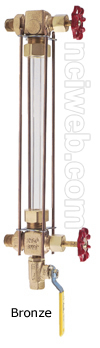

| Bronze Gage Valves Series VA

with Automatic Shut-Off: |

| Model No. VA-991 Straight through flow design. Bronze body construction. 5/8" Dia. Glass, 1/2"NPT Vessel Connection. Automatic |

|

| Model No. VA-902 Straight through flow design. Bronze body construction. 3/4" Dia. Glass, 3/4"NPT Vessel Connection. Automatic |

| |

| These tubular glass gage valves feature

Bronze body construction. They come complete with corrosive-resistant

ballchecks for automatic closure in the event of glass breakage. This

ensures safety and prevents the loss of fluid. Maximum

working pressure is 200 psi @ 400°F, or 400 psi @ 100°F . |

|

| Bronze Gage Valves Series VA

without Automatic Shut-Off: |

| Model No. VB-991 Straight through flow design. Bronze body construction. 5/8" Dia. Glass, 1/2"NPT Vessel Connection. Non-Automatic |

|

| Model No. VB-902 Straight through flow design. Bronze body construction. 3/4" Dia. Glass, 3/4"NPT Vessel Connection. Non-Automatic |

| |

| These all Bronze valves are similar

to above models. However, ballchecks are not standard,

thus making operation non-automatic. A 1/4" needle drain

valve in the lower unit accommodates a breakage condition. Either

a 1/4" lower arm ball valve or a pet-cock is available upon request. Sizes,

packing materials and working pressures are identical to above

models. |

|

| Bronze Gage Valves Series

VC with Automatic Shut-Off: |

| Model No. VC-991 Straight through flow design. Bronze body construction. 5/8" Dia. Glass, 1/2"NPT Vessel Connection. Automatic* |

|

| Model No. VC-902 Straight through flow design. Bronze body construction. 3/4" Dia. Glass, 3/4"NPT Vessel Connection. Automatic* |

| |

|

Conforming to A.S.M.E. power-boiler

code requirements, these gage valves feature stainless steel

ball checks in both upper and lower units. This provides

automatic closure in the event of glass breakage and requires

the ball check in the lower valve to rise vertically to its seat. A

safety handle is also provided for manual operation of the 5/16"

diameter drain valve. This valve is of the full-flow

ball valve design. The valve body is constructed of rugged, heavy pattern bronze. Standard

packing materials are wear-resistant Teflon-Asbestos. Maximum

working pressure is rated at 500 psi @ 500°F, or 250 psi @

400°F.

|

|

| Bronze Gage

Valves Series VE without Automatic Shut-Off: |

| Model No. VE-991 Straight through flow design. Bronze body construction. 5/8" Dia. Glass, 1/2"NPT Vessel Connection. Non-Automatic* |

|

| Model No. VE-902 Straight through flow design. Bronze body construction. 3/4" Dia. Glass, 3/4"NPT Vessel Connection. Non-Automatic* |

|

| These gage valves are identical in

every respect to above models, except for the non-automatic design. Ball

checks are not included. |

| * Automatic means the valve comes complete

with a corrosive-resistant ballchecks for "automatic" closure

in the event of glass breakage. This will ensure safety and prevents

loss of fluid. Non-automatic means the valve is provided without

the ballcheck feature. |

|

| Available Literature: |

| {module_literature,c,86535} |

| |

| Previous

Page |