Standard

Chamber Material: Carbon Steel (A696 C), Low Temperature Carbon

Steel (A350 LF2) and 316LSS (A511 Dual Rated for 316SS & 316LSS)

Standard

Chamber Material: Carbon Steel (A696 C), Low Temperature Carbon

Steel (A350 LF2) and 316LSS (A511 Dual Rated for 316SS & 316LSS)- Tempered Borosilicate Glass conforming to BS3463, JIS B8211, DIN 7080 & DIN 7081

- All gages are Hydrostatically Tested to 1-1/2 times the rated pressure at 100º F (38ºC)

- Wetted Parts Conform to NACE MR-01-75

- All Parts are ASTM Grade and listed in ANSI 31.3

- Recessed Gasket Seat in Chamber and Cover

- Covers are Shrouded to Protect the Glass Edge

Specifications:

- Section Lengths: Gage sections are available in nine standard glass sizes. Longer sizes are constructed with multiple vision slots in a continuous solid bar chamber.

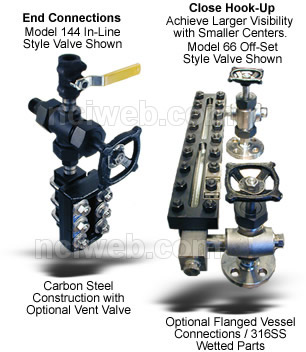

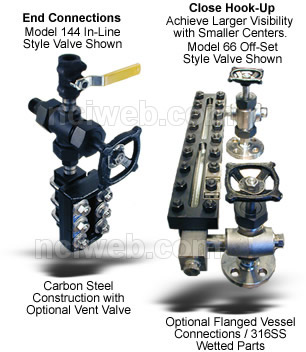

- Connections: Standard connections are at top and bottom and are 1/2" or 3/4" NPT female. Optional connections are available, such as socket weld, flanged or close hook-up (side/side).

- Liquid Chamber: Machined bar stock. The gasket seat is recessed to allow lateral support and facilitate positioning.

- Covers: Forged carbon steel is standard. Optional materials are available such as 316SS. The cushion gasket seat is recessed.

- Bolts & Nuts: Alloy steel is standard, A193 B7 and A194 2H. Optional materials are available. All steel fasteners are "black oxide" treated to prevent rust.

- Glass: Tempered Borosilicate is used to 600° F (316° C). Aluminosilicate is used to 800° F (427° C). Transparent glass may be protected from corrosive media with mica or Neoflon CTFE shields.

- Gaskets: Standard gaskets are precision die cut in proprietary Jerguson dies.

- Finish: All steel parts are finish coated prior to assembly. Stainless steel is not coated.

NOTE: It is recommended that all gages be installed with Jerguson gage valves having safety ballchecks which help provide protection against physical injury and loss of product if glass breakage should occur.

Features/Specifications: (click to open & close)

Features/Specifications: (click to open & close) Specify Gage Assemblies by the Figures given below: (click to open & close)

Specify Gage Assemblies by the Figures given below: (click to open & close) Series 20 Models and Dimensions: (click to open & close)

Series 20 Models and Dimensions: (click to open & close) Options and Adders: (click to open & close)

Options and Adders: (click to open & close) Support

Files / Links: (click to open & close)

Support

Files / Links: (click to open & close)

One of the

simplest techniques for indicating liquid level is by means

of a direct reading device with which the

level can be seen visually. A common method of providing

such visual indication is by installing direct reading gages

in the vessel itself. These direct reading gages are placed

at different locations or points to indicate the liquid height.

More often, separately mounted gage glasses are used to provide

a continuous indication of level over a certain vertical

distance on the vessel.

One of the

simplest techniques for indicating liquid level is by means

of a direct reading device with which the

level can be seen visually. A common method of providing

such visual indication is by installing direct reading gages

in the vessel itself. These direct reading gages are placed

at different locations or points to indicate the liquid height.

More often, separately mounted gage glasses are used to provide

a continuous indication of level over a certain vertical

distance on the vessel.  Standard

Chamber Material: Carbon Steel (A696 C), Low Temperature Carbon

Steel (A350 LF2) and 316LSS (A511 Dual Rated for 316SS & 316LSS)

Standard

Chamber Material: Carbon Steel (A696 C), Low Temperature Carbon

Steel (A350 LF2) and 316LSS (A511 Dual Rated for 316SS & 316LSS)