Float & Thermostatic Steam Traps

|

|

Float & Thermostatic

steam traps are preferred for efficient, economical vacuum and

pressure service. F & T

traps are highly recommended for applications where large volumes

of air are present on start-up and where condensing rates can

vary widely. F & T traps are ideal for service in health

care institutions, apartments, educational facilities, offices

and other public areas as well as in business and industry. F & T

traps operate in response to rising and falling condensate levels

and rising and falling temperatures near thermostatic vent. Dimensional

Information Float & Thermostatic

steam traps are preferred for efficient, economical vacuum and

pressure service. F & T

traps are highly recommended for applications where large volumes

of air are present on start-up and where condensing rates can

vary widely. F & T traps are ideal for service in health

care institutions, apartments, educational facilities, offices

and other public areas as well as in business and industry. F & T

traps operate in response to rising and falling condensate levels

and rising and falling temperatures near thermostatic vent. Dimensional

Information

- Choose from 21 standard capacity models

- Models available in five connection sizes from

1/2 in. to 2 in..

- Designed for ease of installation and simplified, minimal

maintenance.

- Time tested design and quality materials for longer service

life.

- Designed specifically for maximum condensate removal at six

different pressure ratings.

Install F&T traps in steam applications such as Instantaneous

Heaters, Steam Humidifiers, Steam-Jacketed Vessels, Unit Heaters,

Sterilizers and other similar equipment. Pictured at right are

diagrams of typical installations.

|

| |

| DEPENDABLE, TROUBLE-FREE FLOAT ACTUATION |

|

F&T traps operate in response to rising and

falling condensate levels and rising and falling temperatures

near the thermostatic vent, as follows:

- Condensate initially fills the trap body to a predetermined

level, which is sufficient to seal the valve seat opening.

- As the condensate level continues to rise, the float

will rise causing the valve to pull away from the seat.

- Condensate will then be discharged into the return

line through the trap outlet. The rise and fall of condensate

level causes a continuous discharge which is typical of F& T

traps.

- Air entering the trap is discharged through the thermostatic

vent. The opening and closing of the vent is dependent upon

the temperature surrounding the thermostatic element.

- As the element cools with more air accumulating, it

opens to allow the air to vent to the atmosphere.

|

|

| STERLCO F&T TRAPS ARE DESIGNED SPECIFICALLY

FOR MAXIMUM CONDENSATE REMOVAL AT SIX DIFFERENT PRESSURE |

| Heating Service: |

Industrial Service: |

Industrial Service |

| 3/4" through 2" NPT

- Vacuum to 15 psi |

3/4" and 1"NPT

-to30psi |

3/4, 1", 1-1/4"NPT

-to 75 psi |

|

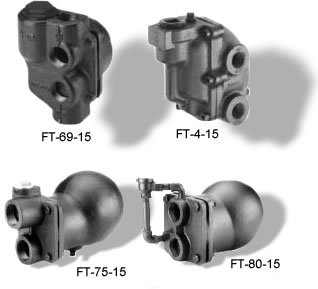

3/4" FT-69-15

|

3/4" FT-3-30

|

3/4" FT-56-75

|

| 3/4" FT-3-15 |

1" FT4-30 |

3/4" FT-3-75 |

| 1" FT-4-15 |

|

1" FT4-75 |

| 1"FT 74-15 |

|

1"FT57-75 |

| 1-1/4" FT-75-15 |

|

1-1/4" FT-58-75 |

| 1-1/2" FT-78-15 |

|

|

| 2" FT-80-15 |

|

|

| |

|

|

| Industrial Service |

Industrial Service |

Industrial Service |

| 3/4", 1", 1-1/4" NPT

- to 125 psi |

3/4", 1"NPT

-to 150 psi |

3/4", 1"NPT

-to 175 psi |

|

3/4" FT-86-125

|

3/4" FT-3-150

|

3/4" FT-3-175

|

| 1"FT 87-125 |

1"FT4-150 |

1"FT4-175 |

| 1-1/4" FT-88-125 |

|

|

| |

|

|

|

|

|

| |

| |

|

|

|

Pressure

Differential, PSI

|

|

|

|

114

Lb.

|

112

Lb.

|

1

Lb.

|

2

Lb.

|

5

Lb.

|

10

Lb.

|

15

Lb.

|

|

Model

Number

|

Size

|

Capacities

in lbs. of Condensate

|

per

hour

|

|

FT-69-15

|

314

|

70

|

100

|

140

|

200

|

210

|

220

|

230

|

|

FT-3-15

|

314

|

70

|

100

|

140

|

200

|

210

|

220

|

230

|

|

FT-74-15

|

1

|

175

|

250

|

350

|

500

|

525

|

550

|

575

|

|

FT-4-15

|

1

|

175

|

250

|

350

|

500

|

525

|

550

|

575

|

|

FT-75-15

|

1114

|

425

|

600

|

850

|

1200

|

1260

|

1320

|

1380

|

|

FT-78-15

|

1112

|

850

|

1200

|

1700

|

2400

|

2520

|

2640

|

2760

|

|

FT-80-15

|

2

|

1775

|

2500

|

3550

|

5000

|

5250

|

5500

|

5750

|

|

|

|

| |

| Discharge Capacities - Acutal Ratings to 175psi |

|

|

|

Pressure

Differential, PSI

|

|

|

|

112

|

1

|

2

|

5

|

10

|

15

|

20

|

30

|

50

|

60

|

75

|

100

|

125

|

150

|

175

|

|

Model Number

|

Size

|

Capacities

in lbs. of Condensate per hour

|

|

FT-69-15

|

314

|

400

|

560

|

800

|

840

|

880

|

920

|

|

|

|

|

|

|

|

|

|

|

FT-3-15

|

314

|

525

|

700

|

975

|

1370

|

1870

|

2225

|

|

|

|

|

|

|

|

|

|

|

FT-4-15

|

1

|

525

|

700

|

975

|

1370

|

1870

|

2225

|

|

|

|

|

|

|

|

|

|

|

FT-74-15

|

1

|

750

|

1050

|

1500

|

1575

|

1650

|

1725

|

|

|

|

|

|

|

|

|

|

|

FT-75-15

|

1114

|

1800

|

2550

|

3600

|

3780

|

3960

|

4140

|

|

|

|

|

|

|

|

|

|

|

FT-78-15

|

1112

|

3600

|

5100

|

7200

|

7560

|

7920

|

8280

|

|

|

|

|

|

|

|

|

|

|

FT-80-15

|

2

|

7500

|

9180

|

15000

|

15750

|

16500

|

17250

|

|

|

|

|

|

|

|

|

|

|

FT-3-30

|

314

|

300

|

410

|

580

|

1050

|

1410

|

1620

|

1830

|

2130

|

|

|

|

|

|

|

|

|

FT-4-30

|

1

|

300

|

410

|

580

|

1050

|

1410

|

1620

|

1830

|

2130

|

|

|

|

|

|

|

|

|

FT-3-75

|

314

|

155

|

215

|

300

|

515

|

680

|

840

|

960

|

1140

|

1410

|

1540

|

1676

|

|

|

|

|

|

FT-4-75

|

1

|

155

|

215

|

300

|

515

|

680

|

840

|

960

|

1140

|

1410

|

1540

|

1676

|

|

|

|

|

|

FT-56-75

|

314

|

175

|

240

|

340

|

440

|

770

|

825

|

1085

|

1290

|

2005

|

2235

|

2350

|

|

|

|

|

|

FT-57-75

|

1

|

175

|

240

|

340

|

440

|

770

|

825

|

1085

|

1290

|

2005

|

2235

|

2350

|

|

|

|

|

|

FT-58-75

|

1114

|

185

|

255

|

375

|

730

|

880

|

1280

|

1520

|

1880

|

2980

|

2700

|

2980

|

|

|

|

|

|

FT-86-125

|

314

|

110

|

150

|

200

|

255

|

375

|

450

|

480

|

565

|

690

|

760

|

1265

|

1445

|

1600

|

|

|

|

FT-87-125

|

1

|

110

|

150

|

200

|

255

|

375

|

450

|

480

|

565

|

690

|

760

|

1265

|

1445

|

1600

|

|

|

|

FT-88-125

|

1114

|

180

|

250

|

320

|

430

|

680

|

725

|

950

|

1250

|

1590

|

1760

|

1935

|

2205

|

2445

|

|

|

|

FT-3-150

|

314

|

80

|

115

|

150

|

230

|

310

|

390

|

450

|

540

|

640

|

740

|

820

|

930

|

1050

|

1130

|

|

|

FT-4-150

|

1

|

80

|

115

|

150

|

230

|

310

|

390

|

450

|

540

|

640

|

740

|

820

|

930

|

1050

|

1130

|

|

|

FT-3-175

|

314

|

60

|

80

|

110

|

175

|

250

|

300

|

340

|

410

|

520

|

560

|

610

|

695

|

765

|

820

|

870

|

|

FT-4-175

|

1

|

60

|

80

|

110

|

175

|

250

|

|

|

410

|

520

|

560

|

610

|

695

|

765

|

820

|

870

|

|

|

|

| Dimensional Information |

| |

| Previous Page |